A Comprehensive Guide To Forklift Maintenance

Horvet

The productivity of the manufacturing industry is dependent on the ability of their forklift fleet to handle heavy loads. Every multi-directional forklift requires periodic care and maintenance to increase its efficiency. They are very capable of handling a variety of loads in your industry but would perform even better. This blog will serve as a comprehensive guide to forklift maintenance.

Frequency of Inspection

The inspection frequency is based upon numerous factors such as the nature & hours of operation, previous maintenance checks, safety features, and overall condition. Therefore, account for all of these elements while deciding on the frequency of multi-directional & side loader forklift inspection.

Daily Maintenance

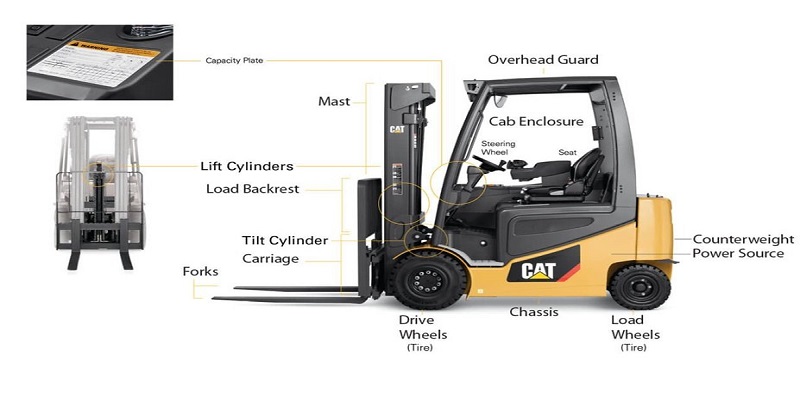

Conducting daily inspections would be very helpful in figuring out any basic faults like break faults or leaks. So, when the operator starts their work for the day, they must check if there are any defects that are visible on sight. Check for the level of fuel, engine oil, mast, and radiator. They need to ensure that nothing affects the functionality of the machine.

Monthly Inspections

A monthly maintenance plan may involve cleaning your forklift’s air filter and checking its drive belt, spark plug, and lift and tilt cylinder after two hundred hours of service. The engine must be replaced while conducting periodic maintenance, and necessary adjustments can be made to the engine’s idle speed. It’s also a good idea to lubricate the mast and chassis components.

Quarterly Inspections

Once the service hours cross six hundred hours, quarterly maintenance is performed. Replacing the hydraulic filters, checking the radiators, hydraulic oil pump, hand brake, and mast operation are some of the things that are checked here.

When the side loaders and multi-directional forklifts are maintained properly, the productivity within the industry will keep improving. Contact Horvert Inc for a wide range of material & pipe handling equipment today.

Related Articles

The Evolution Of Heavy-Duty Load Handling Forklifts

The industry of material handlin

Read More

How C10000 Forklift Is Ideal For Outdoor & Heavy Applications?

Read More

Things You Need To Know About COMBI-4WSL Forklifts

Read More

How Does Your Truck Selection Impacts On Forklift Safety?

Read More

How Forklifts Help In Overcoming The Warehouse Challenges?

Warehouses play a crucial role in logistics, retailers, and many

Read More

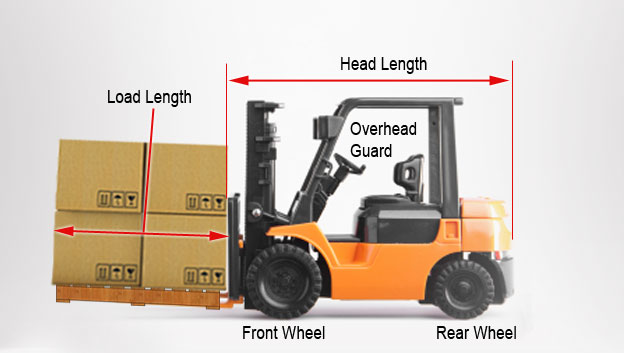

Things To Consider In Calculating Forklift Aisle Width

The forklift is one such equipment that makes your warehouse or

Read More

How To Prepare For A Material Handling While Using A Forklift?

We all know that forklifts significantly enhance the warehouse's

Read More

Guidelines To Consider While Using Forklifts In Outdoors

Forklifts are one such heavy-duty equipment , its contribution Â

Read More

Things You Need To Know About Lockout/Tagout Procedure

We all know that a forklift is o

Read MoreBenefits Of Forklift Tracking And Monitoring System

Forklifts have become one of the essential equipment in the logi

Read More

Which Lift Truck Is Best For Warehouse Facilities?

The warehouse is one of the most happening places where manufact

Read More

Tips On Preventing Forklift Damage

The workplaces like distribution centres, warehouses, logistics,

Read More Previous

Previous

Next

Next

No. 218, 4th Cross, Second Floor, Bhuvaneshwary Nagar Velachery, Chennai – 600042, Tamil Nadu, India

Get A Quote

Designed by Corporality Global