The Evolution Of Heavy-Duty Load Handling Forklifts

The industry of material handling equipment has developed over years to streamline the process of industrial functions in terms of efficiency, safety, and responsiveness. One of the biggest breakthroughs over years of the industry’s innovation is the building of heavy-duty forklifts like multi-directional forklifts. These forklifts have revolutionized the way forklifts operate through warehouses, factories, and many more terrain to handle heavy and long loads. This blog explores the evolution of heavy-duty load handling forklifts through time beginning from the era of industrialization.

Evolution Of Forklifts

The history of forklifts started with simple dollies and lift trucks that were intended to lift and move heavy material in straight-line. Gradually, with the industrial need for increased storage and heavy-lifting, came forklifts that could efficiently move bulky material across the work floor.

Early Innovations (Late 19th – Early 20th Century):

The history of forklift dates back to the late 19th and early 20th century where the industrialist opted for usage of manually operated devices like sack trucks, hoists and hand-powered four-wheel trucks. These devices were used to move heavy goods.

Around 1906, battery-powered trucks were introduced in the market for material handling – marking the change from manual to battery powered equipment.

World War I Era:

The next phase that revolutionized the forklift equipment was during the World War I era due to the shortage of labor paving the way for electric trucks to gain popularity. While the hydraulic lift made its debut in this era, it remained uncelebrated due to difficulties in manufacturing.

But the electric lift truck was a cheaper, more accessible alternative that found its place as the best MHE within the limitations of that time.

Interwar Period (1920s-1930s):

In 1917, a forklift was introduced called “Tructractor” which was designed with a seated counterbalanced truck. Around the year 1923, electric trucks were developed with forks and masts which resemble today’s forklifts. However, in late 1930’s the industry saw standardization of trucks suitable for the pallet size enhancing the efficiency of forklifts

World War II & Post-War Advances:

World War II increased the demand for efficient material handling paving way to the innovation of battery-powered forklifts. This shift allowed for more uptime in forklifts, which the commonly found internal combustion engine forklifts lacked. It is also essential to understand that post-war the warehouses were expanded especially vertically prompting the need for narrow aisle electric reach trucks in 1954.

Modern Developments (1960s-Present):

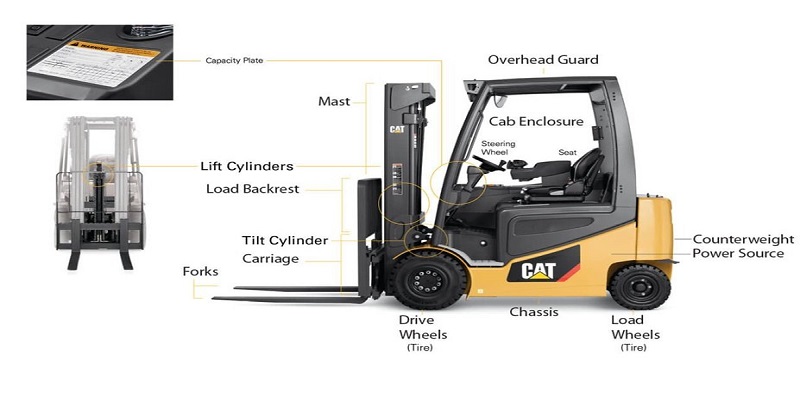

From the 1960’s, the forklifts were introduced with overhead guards and load backrests to protect the operators. In 1980, the forklifts were designed primarily focusing on reducing emissions and leading the advancements in the forklift technologies. At present, the recent trends include the integration of AI, sustainable energy sources and various efficient solutions for enhanced operations.

The most recent innovation in such a wide-reaching material handling industry was achieved by multi-directional forklifts. They spelled an entirely new and improved warehouse management of long and bulky loads. Mobilising movement both forwards AND sideways gave way to maximum space utilization thus increasing storage by more than 50%.

Combilift invented the world’s first i.c. engine powered, all-wheel drive multi-directional forklift – the C-series – in 1998 and has experienced exceptional growth ever since. It now exports its wide range of products to over 75 countries around the world, including India where it is distributed by Horvert Inc.

Combilift C-Series:

The Combilift multi-directional forklift enjoys improved operational efficiency, space utilization, and safety. Here’s why it excels:

Multidirectional Movement

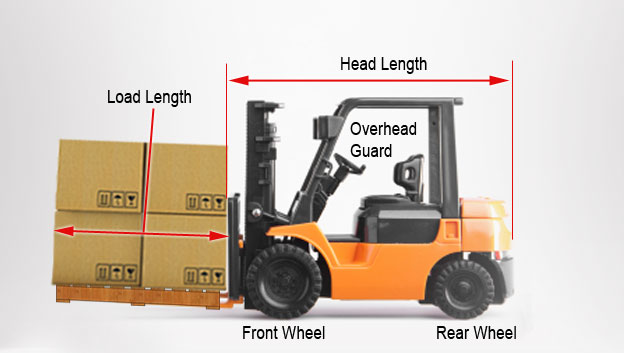

One of the most impressive features of the C-Series is its capability to move in all four directions: forward, backward, and sideways. Instead of altering aisle width to the load’s length, the sideways movement of the C-series lets you minimise the aisle width to just the forklift width alone and move through tight spaces with ease. Once you exit the aisles, the multidirectional movement allows for easy load handling through various terrain.

Handling Long Loads With Ease

The C-Series is specifically designed for handling timber, steel, pipes, and other long materials. Regular forklifts cannot handle such materials because of their length and lack of stability, but the C-Series provides enhanced weight distribution and safe transportation.

More Storage Capacity

Through narrow-aisle operation, Combilift forklifts make maximum use of warehouse storage space. This is an important benefit for warehouses wanting to expand storage capacity without increasing expenditure on more warehouse area.

Safety Improvements

Safety is paramount when handling heavy materials. The C-Series forklifts are equipped with stability control systems, maximized visibility features like warning lights, and fully protected operator cabs to provide safer operation even under tough conditions.

Versatile Power Options

The C-Series comes in diesel, LPG, and electric models to meet the demands of various industries. With the increasing focus on sustainability, Electric models offer an environmentally friendly option without sacrificing performance while providing 25% more uptime.

Future Of Heavy-Duty Forklifts

With industries calling for greater efficiency and sustainability, the next wave of forklift development is driven by automation and electrification. Leading companies such as Combilift are at the forefront, instilling cutting-edge technology and energy-efficient design into their forklifts.

The development of heavy-duty load-handling forklifts has significantly enhanced material handling efficiency. The Combilift C-Series has been a game-changer, providing unparalleled versatility, safety, and space efficiency. The investment in multidirectional forklifts, a container lifting machine, is a move towards operational excellence for industries that operate long and heavy loads.