Beyond Warehousing: How Combilift Supports The Aerospace And Defense Sectors

An industry like aerospace and defense where precision, safety, and efficiency are paramount. So, it is essential to handle large and irregular shaped components which is one of the most common challenges in the logistical industry. Combilift, one of the top leaders for multi-direction forklift in India offers exceptional material handling solutions that goes far beyond the traditional warehousing support. The Combilift innovative and customizable forklifts and handling systems have become crucial for aerospace and defense manufacturers who are striving for operational excellence. Hence, this blog explains how Combilift supports the aerospace and defense sectors beyond warehousing.

Specialized Handling For Irregular And Oversized Loads

The aerospace and defense industries frequently deal with the massive and high-value components including the fuselage sections, missile tubes, radar arrays and wing spars. These components are oversized and vary in shape, size, and sensitivity significantly. The conventional forklifts do not meet this requirement when it comes to safety and navigating through the confined spaces.

The Combilift’s multidirectional forklifts are engineered specifically for these tasks offering unmatched flexibility. Also, these forklifts allow the operators to move the long and irregular shapes of the loads sideways, diagonally, and in the confined indoor spaces without the need of turning. So, with the help of multidirectional movement these forklifts ensure a precise and safe transportation of various components drastically minimizing the risk of damage and collision.

Enhancing Production Line Efficiency

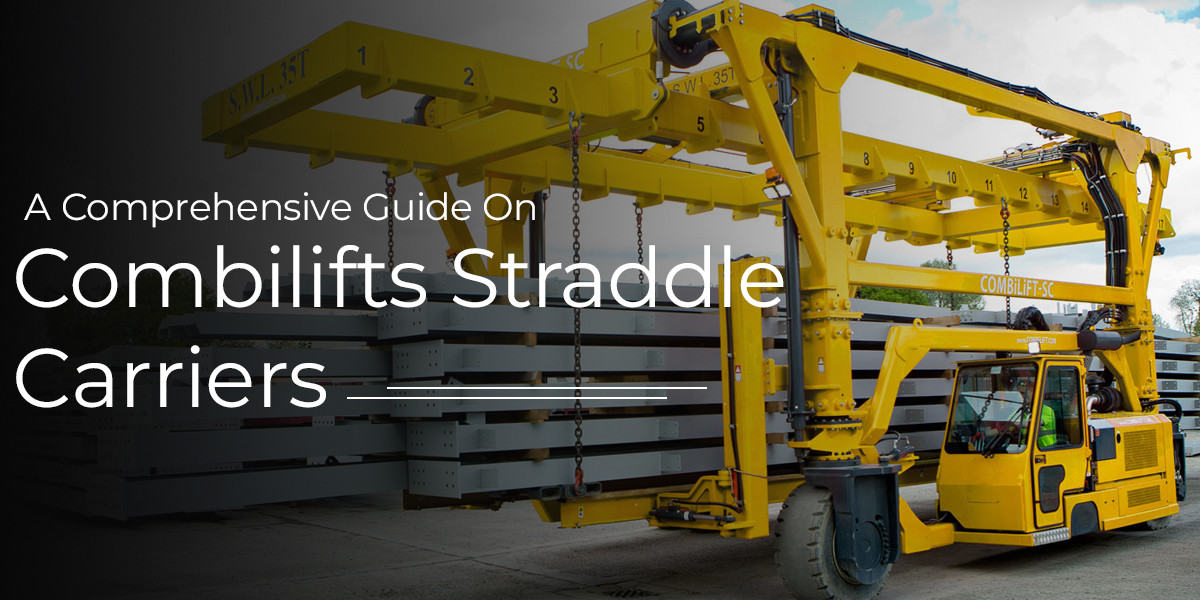

In the defense and aerospace manufacturing, the efficiency saves ample time ensuring there is continuous operation of the process. The Combilift equipment improves the internal logistics of the factories ensuring there is continuous material flow. Also, this equipment reduces the double handling, simplifies storage layouts, and free up the floor space contributing to more streamlined production lines. For example, the Combi-CB is especially effective in moving the longer loads and pallets easily while Combi-SC allows safe handling of bulky and heavy components within the confined environments.

Tailored Solutions And Custom Engineering

The major ability that sets Combilift from the conventional forklift is their commitment to customization. Combilift offers customization for the vehicles rather than offering one-size-fits-all machinery meeting the various challenges of the operations. In the aerospace and defense industry, the components are fragile and irreplaceable where Combilift works directly with the logistics and engineers ensuring load stability, operator visibility and adherence to the strict handling protocols.

Improving Workplace Safety And Compliance

Safety is one of the crucial factors in the sectors which operate under the rigorous regulatory scrutiny. The Combilift equipment is robust with a strong focus on operator safety and load stability. The equipment is featured with low center of gravity, integrated cameras, automatic speed control, and ergonomic cabins reducing the operator fatigue and human error.

Moreover, the ability to reduce manual handling and eliminate awkward lifting processes aligns with occupational safety standards—particularly important when dealing with defense-grade equipment or aircraft parts that must maintain structural integrity.

Global Support And Continuous Innovation

Aerospace and defense are global industries, and Combilift matches this scale with a robust international presence. Their worldwide service and support network ensures that maintenance, training, and spare parts are never out of reach. This global footprint is particularly beneficial for multinational defense contractors and aircraft manufacturers with facilities around the world.

Combilift has proven itself as more than a manufacturer of forklifts—it is a problem-solving partner for the aerospace and defense sectors. By offering tailored, safety-focused, and highly maneuverable handling solutions, approach Horvert for Combilift container lifting machine helping organisations move with precision and confidence in some of the world’s most demanding industries. As aerospace and defense operations grow more complex and global, the role of innovative material handling will only become more essential—and Combilift is poised to lead the way.