How Combilift Improves Workplace Safety Effectively?

One of the major things in the material handling sector is to ensure the workplace has the safest working atmosphere. However, it cannot be attained by just adhering to the effective statutory workplace guidelines but by creating strategic and safety measures across the workplace. Hence, this helps in keeping the potential risks at minimum and encouraging a culture of diligence in the workplace. At material handling sectors, where powered vehicles such as side loader forklift and other heavy duty vehicles work together making the vicinity a place for potential risks. In this blog, we will discuss how Combilift would relatively enhance safety into the working environment for employees.

Combilift – The Right Equipment:

It is an undeniable fact that choosing the right equipment for various material handling ensures safety. Whether it be long loads, light pallets, heavy modular structure, or even a stack of containers, choosing the right container lifting machine or equipment can save you from collisions, product damage, damaged racking repairs, and various accident investigation costs.

Combilift C4000-multidirectional forklift has been the cornerstone in the material handling sector as it provides comprehensive solutions for the business by reducing risks and potential accidents. This forklift is designed for moving in multiple directions, including forward, backward, sideways, and diagonally. The forklift is designed to provide excellent visibility to the operator and equipped with advanced stabilization technology, such as an active steering system and electronic stability control.

Long-Loads:

Combilift’s multidirectional forklift or models are great choices for handling long-loads as these trucks are a combination of side-loader, narrow aisle, and counterbalance forklift. With this model you can easily move 18m beams into the given space. These models are robustic and serve multi-purpose operation for better stability during lifting and transportation of loads, reducing the risk of tip-overs or instability-related accidents These models.extendable forks, side-shift capabilities, and rotating carriages, allows the operators to position loads precisely.

Safer On Foot:

Many companies are looking for advanced push pull equipment which could inherently operate at a walking speed than the motorized trucks.This technology is now incorporated into many models of Combilift to handle small to medium sized pallet loads but not too long as sheets. The Combi-WR, Combi-WR4, and Combi-CS counterbalance are the best option for operators working in the narrow aisle by reducing risk being trapped between the racks. These models have a greater visibility all-around and over the loads, making it a right option for a safer working environment.

Extreme Loads:

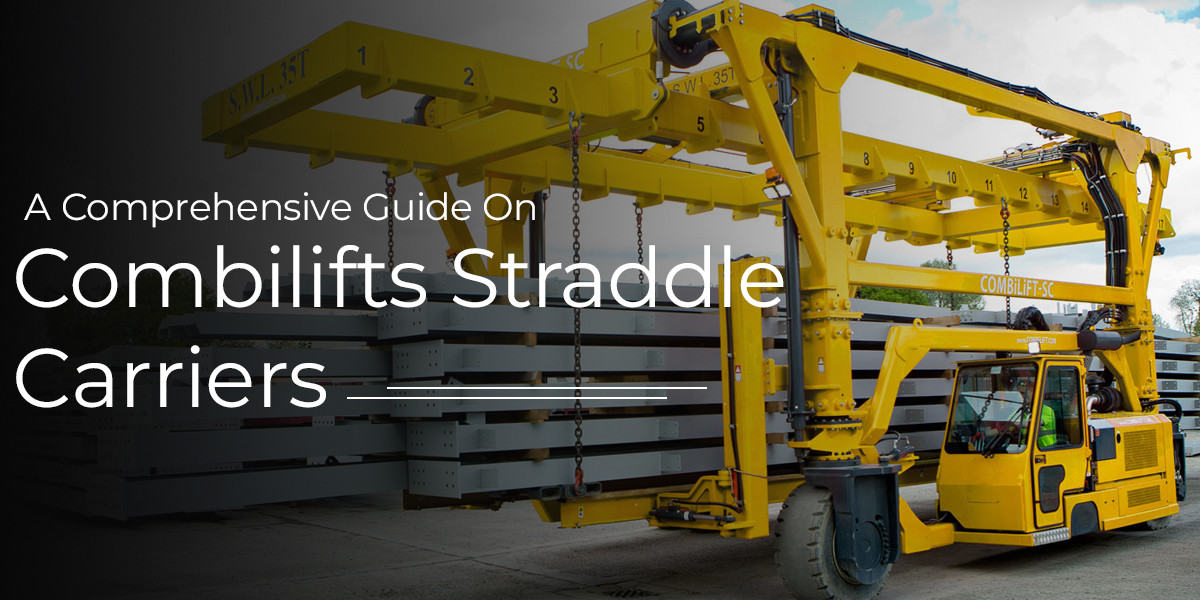

Companies that handle large loads like concrete or structural steel face inherent risks during the loading process, especially during shipments. It often involves working at heights, where personnel stand on the trailers to guide forklift drivers. Combilift’s Combi-SC straddle carriers are specifically designed to lift unevenly distributed loads with utmost stability.

Combi-SC allows for convenient ground-level preparation and secure placement of the entire load. Even the heaviest and most unwieldy loads pose no challenge for the Combi-SC, due to its optimal center of gravity, wide wheelbase, and exceptional three-wheel maneuverability. The Combi-SCs ensure safety in the workplace and reduce load assembly time by half and boost profits.

Hence, these are the ways how Combilift improves your productivity and safety at the same time. Avail these forklifts that are engineered with safety from Horvert the best heavy-duty supplier of Combilift pipe handling equipment, and other trucks to promote a safer working environment for both operators and those working nearby.