Know How Combilift Series Reduces Steel Sector Warehouse Costs

Many steel distribution and fabrication companies might have understood how events can significantly impact their business, especially after COVID-19. Thus, many companies are looking for effective ways to improve warehouse efficiency in the steel sector. The Combilift vehicles, such as side loader forklift, come in handy for the operations by increasing the warehouse storage capacity. Hence, in this blog, we will know how the Combilift series effectively reduces the steel sector warehouse costs.

Why Is It Essential To Improve The Steel Sector Warehouse Costs?

In the steel industry, business owners will take in tons of steel from all corners of the world. For instance, as per the reports in the United States from Federal officials about a commitment states that steel manufacturers who are not only the largest direct purchaser in the world but also major infrastructure funders have adopted “buy clean” policies in their steel purchasing practices.

Meanwhile, the European construction industry is still stabilizing after the impact of the COVID-19 pandemic, and supply chains have yet to recover fully.

In such a global environment, the steel storage is significantly affected and as a result the sectors are looking for improved warehouse efficiency. Thus, it is essential to improve the steel sector warehouse operations to reduce the steel waste in their process.

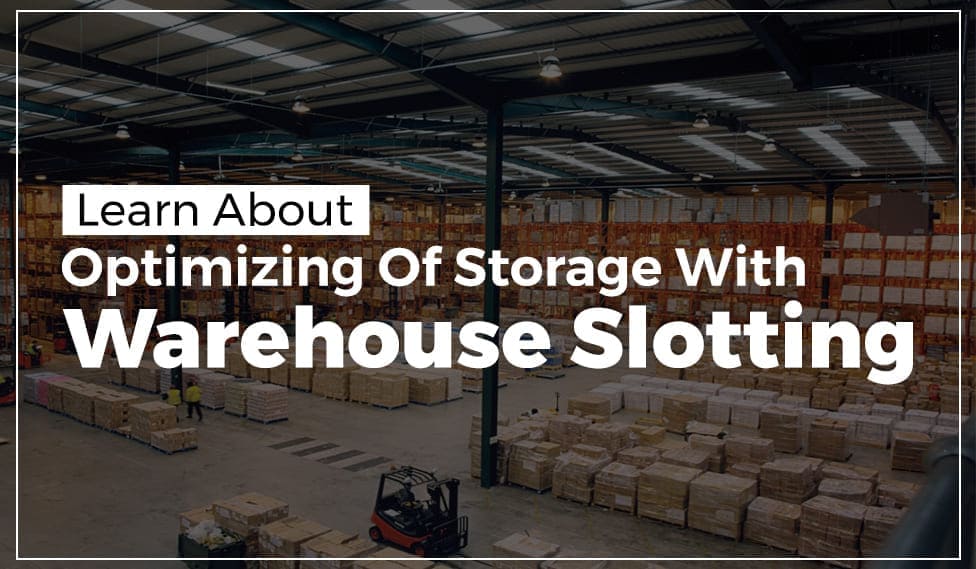

On-Site High Storage Capacity:

To reduce the unexpected costs that occur during the facility dependence.

Lower Reliability:

Warehouse optimization helps when there is high demand.

Increased Performance:

It helps in the safer, simpler, and quicker handling of products.

How Combilift Helps In Achieving The Warehouse Optimization?

The following are the Combilift C-series that will help you to improve steel warehouse efficiency.

C Series: The Original Multidirectional Forklift

This Combilift C-series enhances the workflow by combining a sideloader’s functionality, and narrow aisle forklift into a single vehicle. It also reduces the cost of double handling and has the ability to move in any direction.

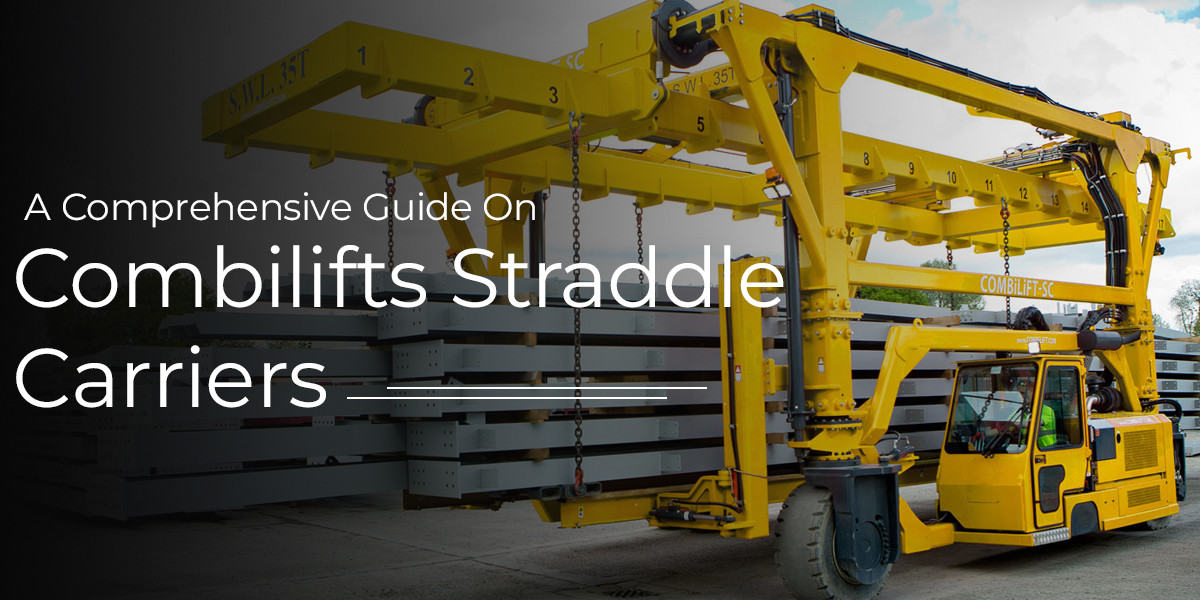

Combi-SC: The Ultimate Solution For Transporting Steel

The Combi-SC, straddle carriers range offers the most cost-effective handling solution for steel fabrication or various distribution facilities to deal the heavy and oversized loads. This Combi-SC increases the maneuverability, smaller footprint, and has customization options to transport steel and oversized loads independently.

Combi-CB: The Compact Multi-Directional Forklift

Similar to the original multidirectional forklift truck, this Combi-CB is more compact than conventional forklifts, making it ideal for transporting palletized loads. In addition, it allows you to carry long loads sideways.

Combi-GT & Combi-ST:

These Combi-GT and Combi-ST ranges are your go-to options when handling steel in enclosed spaces. They offer excellent visibility, efficient guided aisle operation, and a cab designed for maximum productivity, making them ideal for tight spaces.

Hence, instead of attempting efficiency through a generic materials handling fleet, choosing Combilift series that are purpose-built vehicles which brings in multiple benefits, especially in times where efficiency gains are crucial. Horvert, the best supplier of Combilift container lifting machineright from forklifts to various heavy duty cantilever racks is your right choice to improve your warehouse efficiency.