Things You Need To Know About Lockout/Tagout Procedure

Horvet

We all know that a forklift is one of the most important devices which not only improves efficiency of the work but also the productivity of the business. But what if your forklift goes down for some unknown reason and what will be the first task from the facility supervisor?

The foremost task from the supervisor’s end will be the lockout/tagout procedure (LOTO). Be it a multi-directional or side loader forklift, LOTO procedure should be followed as soon as the machine stops working to prevent the unexpected dangers and accidents.

Lockout/tagout procedure is nothing but a parameter or procedure where the vehicle goes to the shut-down or released from its energy source to ensure the safety of the workers and machines. It is a preventive measure to stop the further damage of the product and machine operator as well. Hence, in this post, let us look at the things you need to know about the in-depth lockout/tagout procedure

How To Create A Lockout/Tagout Procedure?

The most important part in the LOTO procedure is creating the right constraints because it should be so simple that even a new person should understand when he or she reads. The LOTO procedure should be followed in any device like a push pull equipment. So, it is essential to create the lockout/tagout procedure in a detailed way to ensure safety.

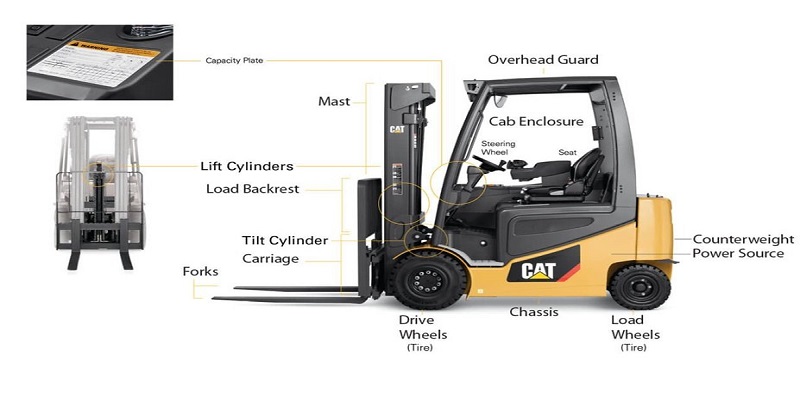

In most of the LOTO procedures, the forklift is attached with a locked box, white, and red warning tag on the steering wheel. So, the lockout device stores the energy and prevents the further activation of the powered trucks. In the case of tagout, the warning tags gives the information to the operator why it is locked.

How Does It Work?

Every forklift works on different aspects but mostly follows the below listed ways. They are,

- Notify the workers

- Use normal procedures to shut down the system

- Isolate the system from other energy sources

- Implement lockout/tagout procedure

- Make sure the system is isolated

When Do You Need LOTO Procedure?

In most of the warehouses and logistics, the LOTO procedure is carried out during the malfunctioning of machines. But, the procedure can also be taken forward during the maintenance. You can implement LOTO procedure during,

- Servicing

- Hot tap work

- Plugging issues

- Normal operations

Hence, these are the essential things that you should know about lockout/tagout procedure. Therefore, approach Horvertinc, the best heavy duty vehicle supplier like ISO container lifting, forklifts, and more for your logistics needs.

Related Articles

How To Achieve Maximum Space Utilization In Your Warehouse?

One of the critical factors in w

Read More

The Evolution Of Heavy-Duty Load Handling Forklifts

The industry of material handlin

Read More

A Comparison Between Multidirectional & Traditional Forklifts

Read More

How C10000 Forklift Is Ideal For Outdoor & Heavy Applications?

Read More

C5000 XL: The Heavy-Duty Material Handling Solution for Every Industry

Read More

Revolutionizing Material Handling: COMBI-SL4500 Multi Directional Forklift

COMBI-SL4500 Read More

A Guide On Maximizing Warehouse Efficiency with the COMBI-CB Forklift

Efficiency is paramount in moder

Read More

How C-Series Multidirectional Forklift Helps Food Manufacturers?

Read More

Why Combilift Model -C4500 E Multi-Directional Forklift Is An Ideal Aluminium Extrusion Equipment?

Read More

Things You Need To Know About COMBI-4WSL Forklifts

Read More

How Heavy Duty Cantilever Racks Are Best For Industrial Storage?

Read More

How is COMBI-CBE Multi Directional Forklift Used In the Timber Industry?

Read More

Know Why Choosing COMBI-FWSL is Ideal For the Steel Industry

Read More

Know About The Special Features Of COMBI-MR Multi Directional Forklift

Read More

COMBI-WR4 The Best Pipe Handling Equipment – Why?

Read More

Multi-Directional Forklifts Enhance Extrusion Processes

Read More

How To Create Safer & Efficient Storage Facilities?

Read More

How Does Your Truck Selection Impacts On Forklift Safety?

Read More

How Does Combilift Series Help You In Optimizing Your Outdoor Space?

Read More

Why COMBI-MR4 Is A Must In Logistics?

Read More

How Forklifts Help In Overcoming The Warehouse Challenges?

Warehouses play a crucial role in logistics, retailers, and many

Read More

Things To Consider In Calculating Forklift Aisle Width

The forklift is one such equipment that makes your warehouse or

Read More

How To Prepare For A Material Handling While Using A Forklift?

We all know that forklifts significantly enhance the warehouse's

Read More

Guidelines To Consider While Using Forklifts In Outdoors

Forklifts are one such heavy-duty equipment , its contribution �

Read MoreBenefits Of Forklift Tracking And Monitoring System

Forklifts have become one of the essential equipment in the logi

Read More

Which Lift Truck Is Best For Warehouse Facilities?

The warehouse is one of the most happening places where manufact

Read More

Tips On Preventing Forklift Damage

The workplaces like distribution centres, warehouses, logistics,

Read More Previous

Previous

Next

Next

No. 218, 4th Cross, Second Floor, Bhuvaneshwary Nagar Velachery, Chennai – 600042, Tamil Nadu, India

Get A Quote

Designed by Corporality Global