Why Use Side Loader Forklifts In Your Warehouse?

Your warehouse operations need the right equipment to increase productivity.

Particularly when you are in the business of handling long profiled goods.

Every day, a lot of goods go back and forth within a short time.

The traffic is busy No matter the complexity of the operation, you can stay optimized with the right solutions. Wonder what can improve the speed and safety of your warehouse when handling long and bulky goods?

That is where the side loader forklift comes into the picture. So, why use sideloader forklifts in your warehouse?

There are so many benefits to be derived from using these forklifts. It is not the standard forklift but a little different. This blog post will highlight the key factors that will persuade you to use sideloader forklifts for warehouse operations.

The standard operation process

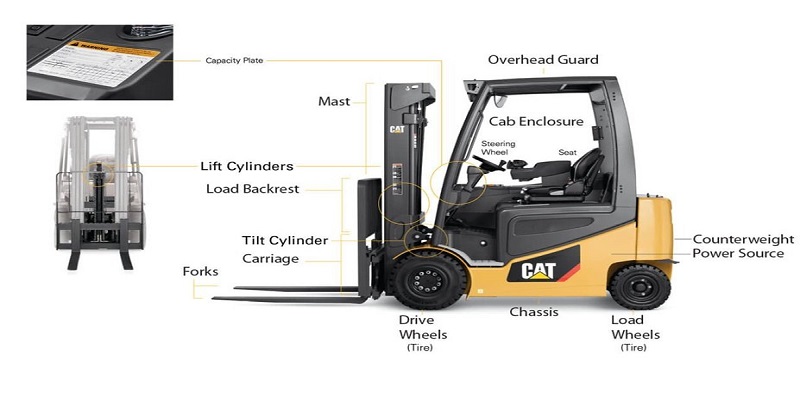

Generally, a warehouse is equipped with a counterbalance forklift

This is good for handling cubical loads example: pallets. The key factor to consider buying in this scenario is the profile of the goods. A warehouse manager will first decide upon the good length and other parameters including gross weight. Then, the mast heights and their types | Fuel whether Electric or diesel Once all the basics have fallen into place, finally, other elements that contribute to safe handling and transportation.

Demands of the modern warehouses

However, the decision cannot be made only with those factors in mind. The complexity in the modern-day warehouse has increased a lot. To meet the demands of the present logistics scenarios, other factors should also be included while making a choice:

- Stacking efficiency

- Loading bays

- Lifting capabilities

- Aisle widths

- Versatile performance

With standard forklift. Meeting all the above is highly risky and inefficient not it. Therefore, companies primarily producing long profiled loads need to look for other advanced options such as the multi-directional forklift. It becomes easier to handle the warehouse operations with sideloader forklifts.

Benefits of using a sideloader forklift

Steel, timber, pipes, Billets, extrusions, Frames, Booms, Structural, precast do not always come in small-sized packages.

Sideloader forklift makes it easy to transfer long loads indoors and outdoors, seamlessly, stack them in racks, and carry loads across rough terrains.

The primary benefit comes from the design of the forklift itself. Unlike the standard models, the load is carried on the side of the vehicle. It provides enough visibility for the operator. Therefore, there are very few chances of accidents or mishaps at the warehouse.

The forks reach out from the center of the bed to lift the long load in the middle. It keeps the load stable while moving it.

Since the goods are taken sideways, the forklift can easily travel through narrow aisles and uneven surfaces. The operator can also safely transport the goods without having to raise them frequently to avoid obstacles in the way.

Above all, the biggest benefit is that the warehouse storage will also maximize the warehouse storage space. Due to the design of the forklift, fewer gaps between rows are needed. Therefore, in a space where ten rows were possible, by using a sideloader forklift, the number becomes twenty.

Horvert Inc deals with a wide range of material handling equipment like power pusher, multi-directional forklifts, and many more. Consult our experts for the right equipment that can increase the operational efficiency of the warehouse.