Why Combilift Model -C4500 E Multi-Directional Forklift Is An Ideal Aluminium Extrusion Equipment?

Understanding Aluminium Extrusion

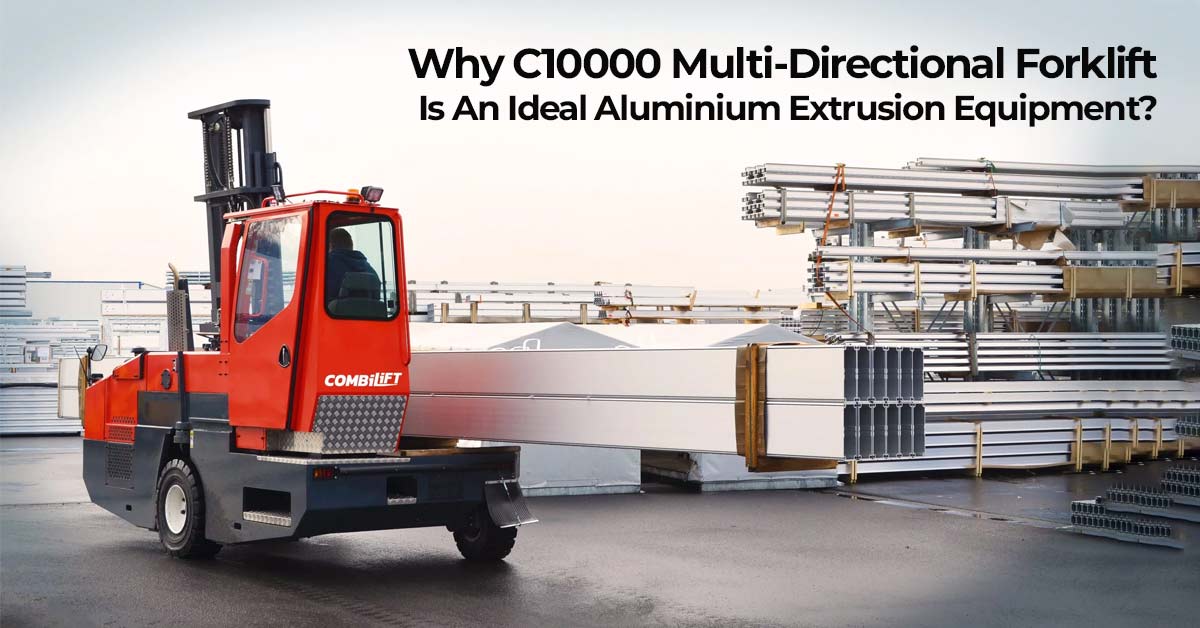

Aluminium extrusion is a process in which aluminium billets are heated and passed through a specialised machine to create lengthy aluminium profiles. These profiles are then reduced at desired lengths and used by various industries like manufacturing, automobile, and many more. The process requires precision handling and transportation of heavy aluminium profiles which is a challenging job, where specialised equipment like the C4500 Multi-Directional Forklift comes into play.

Unmatched Performance:

The aluminium extrusion equipment offers exceptional specifications, making it most preferred for the aluminium extrusion industry. With a lifting capability of 4000 kg – 4500kg , it effortlessly handles heavy loads, ensuring performance and reliability in each operation. Its lifting reach capacity is around 4000 mm, and above4.0mtr this can be customized … Thus providing ample vertical reach and accommodating various extrusion storage provisions r. The platform length of this equipment is is around 1250 mm offering enough space for numerous extrusion profiles ensuring stability at every stage in the process. This device uses a Electric power or diesel engine power , delivering exceptional performance and durability, making it a reliable equipment in challenging environments. Hence, with these functions the equipment offers enhanced performance, versatility, and durability in the aluminium extrusion industry.

Efficient Handling Of Extrusions:

Long profiles and heavy bundles are common in aluminium extrusion facilities. The C4500 multi-directional forklift is able to move in various directions allowing it to handle these large profiles efficiently. Whether stacking profiles, moving them to storage, or transferring them to processing areas, the C4500 multi-directional forklift ensures smooth and accurate handling.

Optimising Storage Solutions:

Aluminium extrusions are frequently stored in racking wit h tight aisle space for accomodating more storage levels , that can be challenging with conventional forklifts. The Combilift model C 4500 multi-directional forklift makes navigating those narrow areas smoothly either to retrieve or store the extrusions effectively.

Improving Workflow And Productivity:

The C 4500 multi-directional forklift complements overall workflow by reducing the need for multiple equipment and streamlining operations. Its versatility approach results in fewer interruptions and faster turnaround times, contributing to higher productivity.

Reducing Damage And Waste:

Accurate handling of delicate aluminium profiles is crucial to avoid damage and waste. The C 4500 multi-directional forklift offers precise control and stability to prevent accidents and ensure that extrusions are moved without scratches or other damage.

Enhancing Safety:

Safety plays a crucial role in any manufacturing industry. The C 4500 multi-directional forklift includes safety features like advanced braking system and load stabilisers. These functions protect the operators and equipment from the risks of accidents.

Maintenance And Care

Regular maintenance and care are essential to ensure efficient performance and sturdiness of the C 4500 multi-directional forklift. It includes:

Routine Inspections:

It is essential to have inspection regularly for the forklift’s hydraulic structures and components as it helps in identifying the issues much earlier than they occur.

Proper Lubrication:

It is also important to keep the working parts of the forklift well-greased for smooth operation and prevent damages.

Operator Training:

In addition, the operators should be educated about the C 4500 multi-directional forklift usage for enhanced performance and preventing the accidents.

The C 4500 Multi-Directional Forklift is the right option for aluminium extrusion operations. Its advanced features, which include multidirectional capability, heavy load bearing capacity, and improved visibility, make it the best option for managing aluminium profiles appropriately and safely. By integrating the C 4500 into the operations, the extrusion industry can increase productivity, reduce damage and waste, and enhance the workflow. As the aluminium extrusion industry evolves, devices like the C 4500 will bring in innovation and efficiency. Investing in such specialised equipment with Horevert the best supplier of heavy-duty equipment to stay ahead of the competition and ensure that your operations run smoothly and efficiently.