A Comparison Between Multidirectional & Traditional Forklifts

The Traditional Forklift

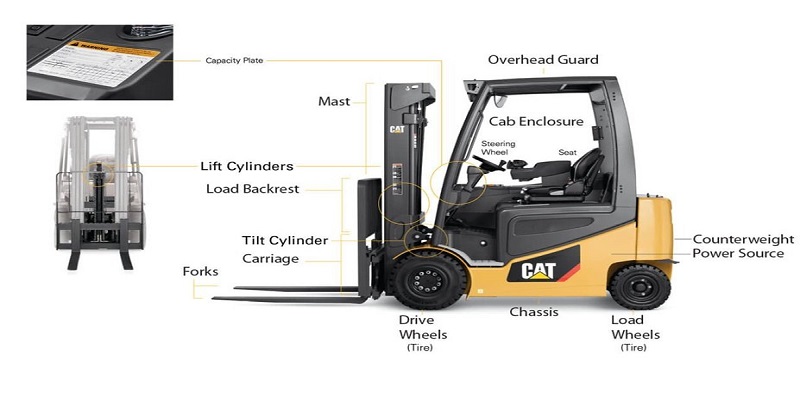

The general description of a forklift is an industrial power truck that specialize in carrying and transporting materials of heavy weights, unmanageable through just human effort, by adding mechanisation in load handling. There are different types and variations in forklifts, depending on the application, size, lift capacity and height reach, each possessing its own benefits. The most common and cheapest option preferred in the larger market is the straightforward Warehouse Forklift with a limited lift height of 6m and 5 tons capacity.

To complete one full cycle of [offloading > transport > storage] and vice versa, using just the traditional forklift is infeasible, and as such different machines are required for outdoor & indoor use. The throughput of such a procedure is at its maximum, 1 & 1⁄2 hours per cycle- which means the per day productivity is restricted to just 6 to 7 cycles per day.

The experienced operation managers are aware of the need for a customized and versatile material handling equipment, to maximise the throughput and increase productivity, without compromise. Multi-directional Forkliftis the perfect choice for achieving this.

What Is A Multi Directional Forklift?

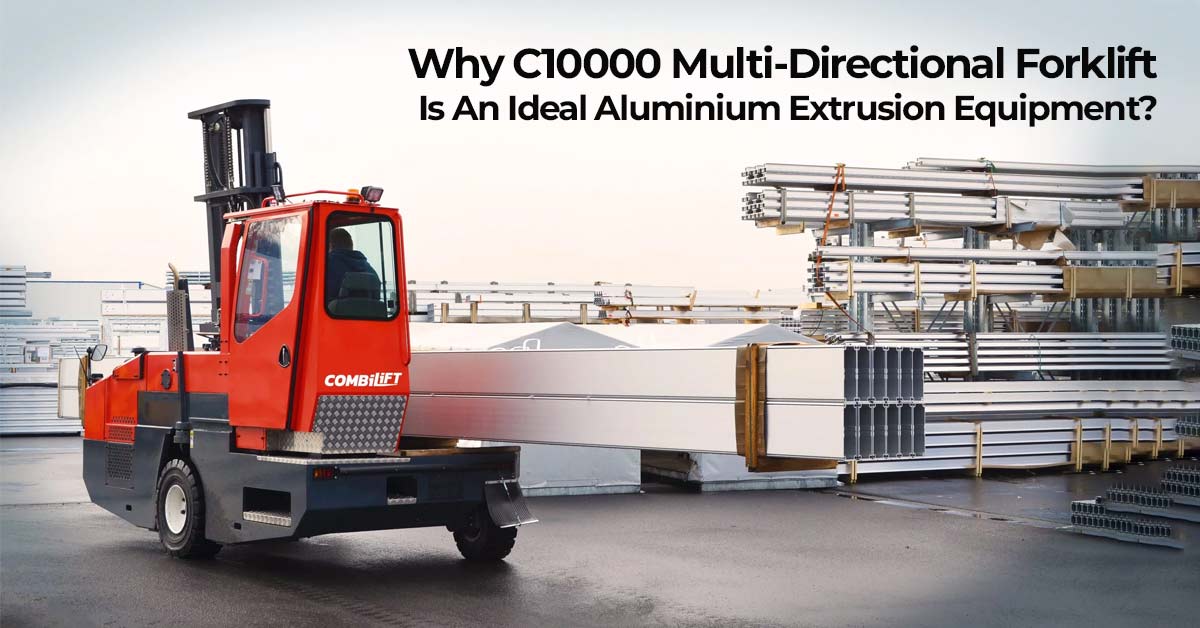

A multidirectional forklift moves in both directions; to and fro or sideways. This ability to travel in the X and Y axis, allows the machine to squeeze into narrow aisles without needing to unnecessarily increase aisle width. It’s also designed with supportive platforms on either side of the forks, for safe transport of long loads without elevation. The Combilift C-series multidirectional forklift is the highest sold in India, given its ease of use and operator-friendly approach to material handling.

In addition, the Combilift C-series is extremely cost effective; It can be used both indoor and outdoors, facilitating smooth cycle of [offloading > transport > storage] and vice versa. Thus, it increases throughput of any production/storage facility by a whopping 50%. Where once 6 to 7 cycles per day was the maximum, with this multidirectional forklift, 10 cycles per day becomes easily achievable.

Pros Of Multidirectional Forklift:

Space efficiency:

Studies show that warehouses using multidirectional forklifts can improve space usage by up to 30% compared to those using traditional forklifts. This is because they can navigate tighter spaces, making them a great choice for smaller warehouses.

Time Savings:

According to the research from the Industrial Truck Association, multidirectional forklifts can also improve efficiency by 25% to 30%. As it can move in any direction, workers spend less time maneuvering, and the flow of goods is faster.

Cost Efficiency:

Even though multi directional forklifts are more expensive they operate for longer, improve productivity and reduce the time spent moving goods. This can make them worth the extra investment, especially for businesses with limited space.

If you have limited budget, wide aisles and plenty of space then opt the traditional forklift. They are less expensive and work great for open warehouse areas.

Opt for a multidirectional forklift if you work in tight spaces or large expansive workfloors , such as narrow aisles or large production areas spanning across acres of land. They provide excellent maneuverability and are more space-efficient

Key Differences

| Feature | Combilift Multi Directional Forklift | Traditional Forklift |

| Maneuverability | Can move in all directions (sideways, forward and backward) |

Forward and Backward only |

| Space Efficiency | Narrow Aisle forklift with minimal turning radius. |

Larger turning radius required |

|

Weight Capacity |

2,500 to 25,000 tons | 3,000 to 5,000 tons |

| Lift Height | Up to 10m | Maximum 6m |

| Cost | More expensive due to advanced features |

Cheaper |

|

Best Use |

Long and Bulky loads; perfect in high density racking systems | Regularly sized cubical loads |

| Ease of Use | Easy and ergonomic | Simple design and minimal movement variation |

| Throughput | At least 50% more than usual | Low |

| Versatility | Indoor and outdoor, even across uneven gravelly surfaces |

Only indoor warehouses |

Both traditional and multidirectional forklifts offer great benefits depending on the layout and needs of your warehouse. If your space is tight and you need flexibility, a multidirectional forklift will help you work more efficiently. Choose Horvert, the best supplier of Combilift container lifting machine so that you can choose the right one for your operation.