Enhance Safety & Efficiency With The M1 Industrial Electric Pusher

The overall market size of the material handling equipment industry is around USD 26.10 Billion in 2024, which is expected to grow to 98.64 Billion by 2034 at a CAGR of 14.22%. It is, however, a certainty that the overall material handling systems will be driven primarily by the increase in mechanization and robotics by the end of 2034. Also, with the increased usage of e-commerce platforms and digital technology, there will be a guaranteed increase in the use of automated warehouse equipment for enhanced operation. The prime driving factors of any such automation will always be the need for efficiency, sustainability and safety.

The M1 industrial electric power pusher is one such innovation in material handling equipment that aligns perfectly with the evergreen needs of the industry, while being the perfect specimen for the automation and technology demanded by futuristic innovation. This blog explores the M1 industrial electric pusher for all its revolutionary aspects.

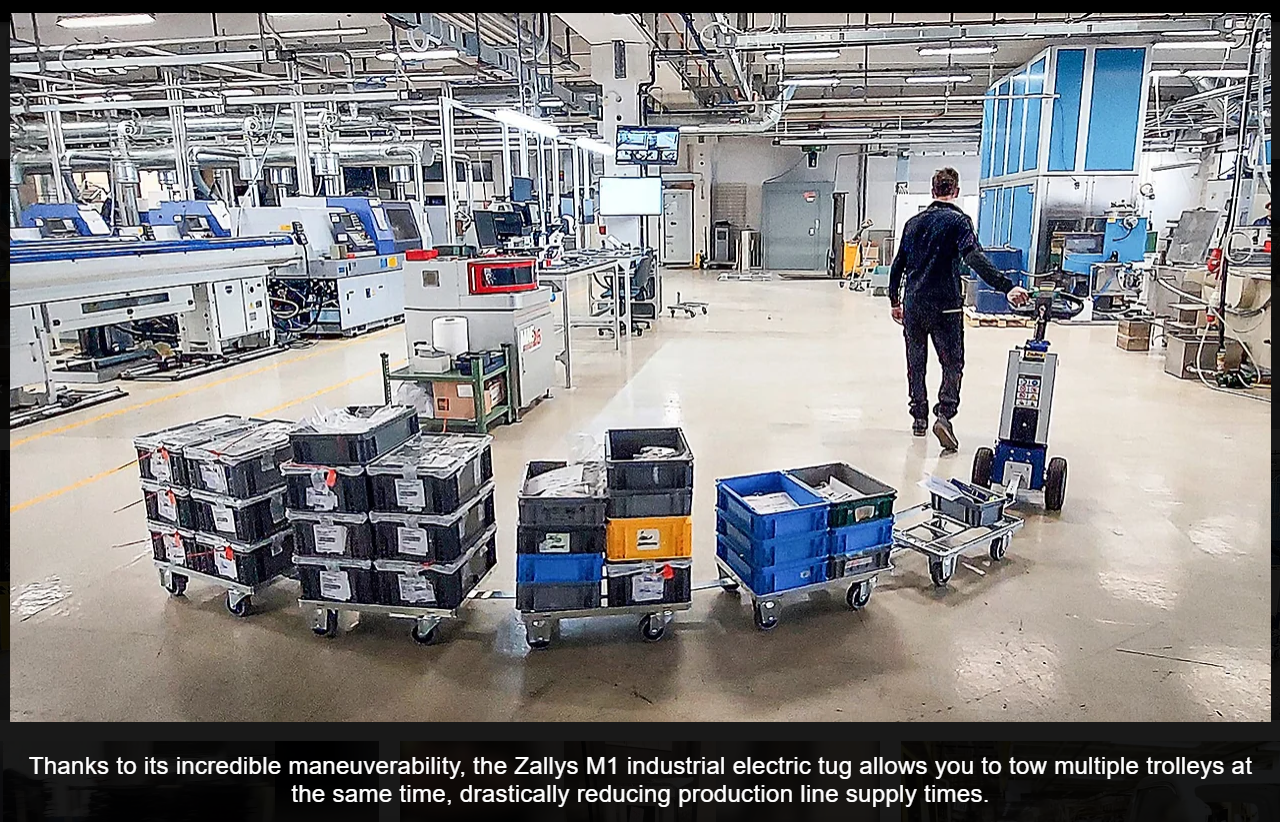

Compact Design and High Maneuverability

Most modern warehouses have narrow aisles, making it difficult for traditional equipment, such as forklifts, to move about conveniently; especially when working with the heavy loads. Incorporating M1 electric power pusher aids in handling loads through narrow corners and aisles, thus enabling seamless operation of the warehouse or plant. The power pusher has a compact design which eases mobility for transportation between the various areas of the warehouse – In most cases, the M1 is less than 30% the size of the load it can move.

Ergonomic And User-Friendly Design

The operation of a warehouse is physically demanding – especially when dealing with heavy loads for long hours. Therefore, it makes the operator feel more fatigued which is a serious concern; leading to decreased productivity, increased error, and potential risks.

The M1 electric power pusher is designed in order to increase the comfort of the operator. This push pull equipment is equipped with ergonomic handles which can be easily gripped and maneuvered. Primarily, this electrically-powered equipment reduces the strain on the operator who handles the bulk force, to move the heavy loads with mechanical ease. Another major advantage is that they are operable with just basic training on operations for any shop floor person. Thus, it cuts down on labour intensity and running cost significantly.

Enhanced Safety Features

Safety plays a crucial role in the warehouse and logistic industry as mishandling of loads can result in serious accidents. The traditional power pushers lack the stability to transport loads securely on uneven surfaces or inclined ones. The M1 industrial electric power pusher bears soft-solid rubber tyres that can withstand indoor as well as outdoor use, and allows loads to be inclined about 15% ensuring consistent and steady movement even under challenging circumstances.

The M1 power pusher also has a controlled speed of 4.0 km/h; reducing the risks associated with fast and unstable movement in warehouse spaces. Thus, the regulated speed offers a complete balance between safety and efficiency as the operators can move heavy loads swiftly without compromising safety.

Adaptability Across All Warehouse Needs

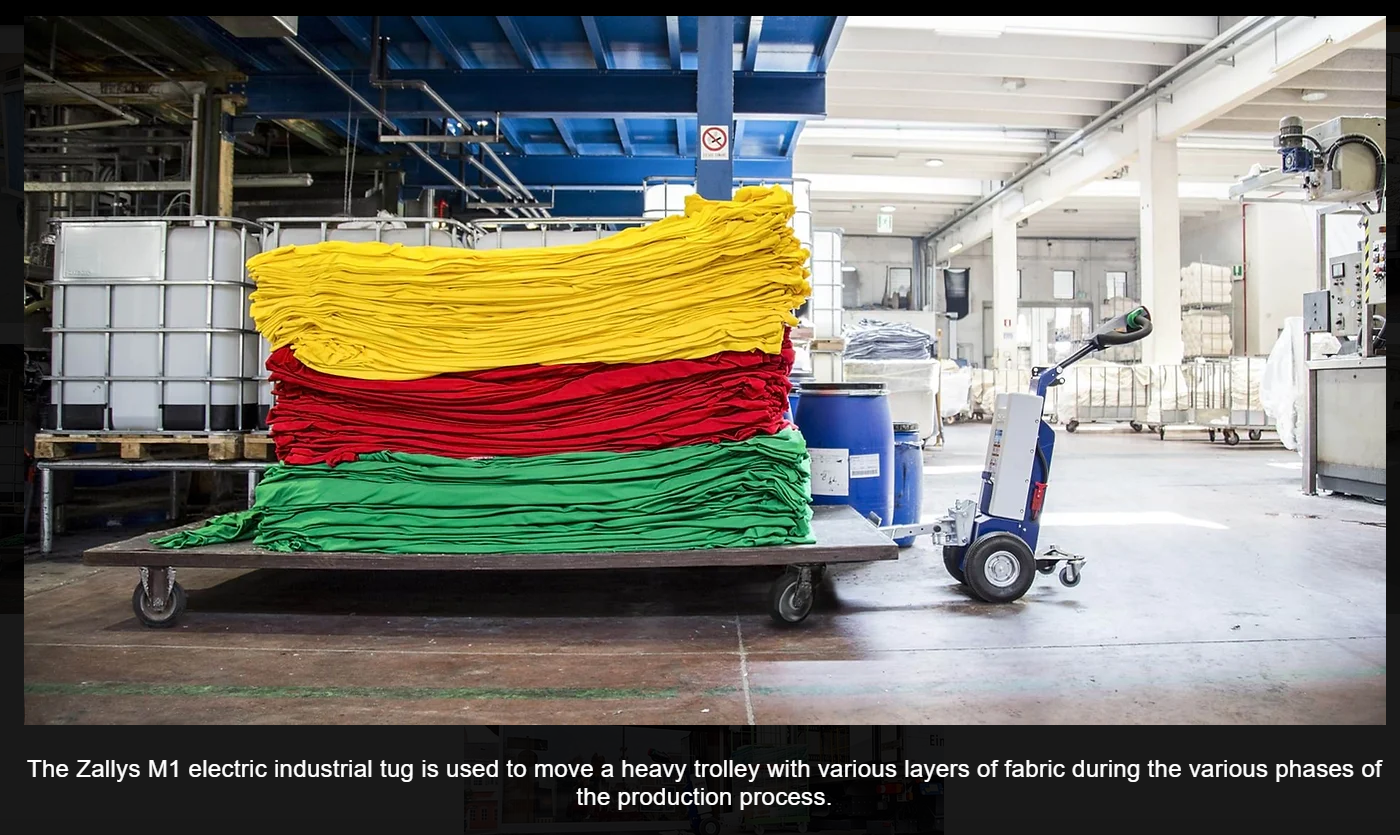

Moving equipment to and from different areas of a warehouse, such as from the storage area to the dispatch area, traditionally requires two or more pieces of equipment to transport the load indoors, then outdoors. The M1 industrial electric power pusher bears soft-solid rubber tyres that can withstand both uses; which allows loads to be tugged directly into the dispatch area, thus providing mobility across different stages of the production line.

This feature is particularly beneficial for businesses that frequently switch between warehouse tasks and delivery operations. For instance, retail warehouses that supply supermarkets and stores can use the M1 for both in-house loading and off-site deliveries.

The M1 industrial electric pusher is a game-changer for warehouses, addressing and overcoming the challenges in a warehouse operation. Its compact design, ergonomic features, enhanced safety measures, adaptability across diverse settings, reliable towing capacity, and rugged build make it an invaluable tool in improving efficiency, safety, and productivity in a warehouse. By reducing operator fatigue, minimizing safety risks, and providing consistent performance, the M1 electric pusher supports smoother, more reliable operations.

Approach Horvert Inc to invest in the M1 for operational efficiency, ensuring you stay in the lead in today’s competitive and fast-paced logistical landscape.