How To Create Safer & Efficient Storage Facilities?

For businesses, secured and efficient facilities are crucial for seamless operation. Whether managing an industrial warehouse or factory, optimizing and creating an efficient and safer atmosphere is essential. Hence, this blog will look into the various critical strategies to achieve the goal, focusing on enhancing safety measures, optimizing storage space, and implementing modern technologies through combilift lifting innovations.

The following are the essential factors to be looked in to optimize your warehouse storage.

Conduct A Comprehensive Risk Assessment:

Before implementing any changes, conducting a thorough risk assessment is essential. Identify potential hazards, both from a safety and security standpoint. It is essential to consider factors like fire risks, structural integrity, and potential security breaches for a comprehensive risk assessment. You can develop a targeted plan to mitigate these risks effectively by understanding them.

Implement Safety Protocols And Training:

Safety should be a top priority in any storage facility. Train the machine operators on best practices for handling goods, operating machinery, and responding to emergencies. Ensure they are equipped with personal protective equipment (PPE) as needed. Regular safety drills and refresher courses should also be conducted to keep safety protocols fresh in everyone’s minds.

Invest In High-Quality Storage Equipment:

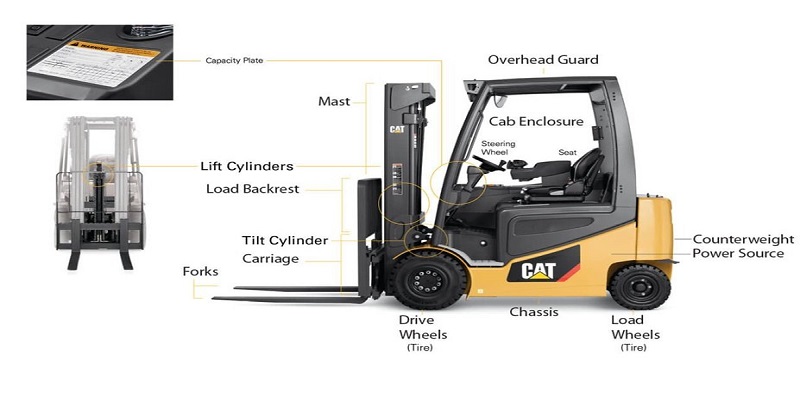

Durable and robust storage equipment is crucial for maintaining a safe and efficient storage facility. Consider pallet racking systems, shelving units, or automated storage systems, depending on your needs. High-quality equipment ensures better load-bearing capacity, minimizes the risk of accidents, and helps organize items more effectively.

How Combilift Helps In Optimizing & Securing Your Warehouse?

Space Utilization:

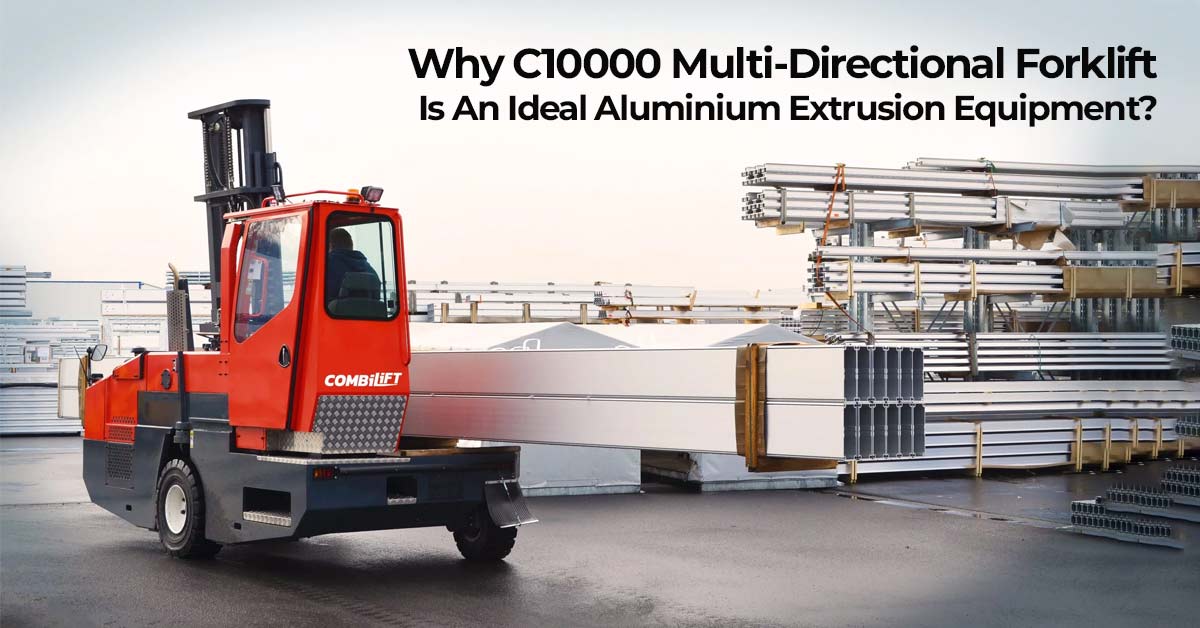

Multi-directional forklift are adept at handling long and bulky loads, making them ideal for narrow aisles and confined spaces. By enabling operators to move loads in multiple directions, these forklifts maximize storage density, allowing warehouses to store more goods in limited space.

Improved Maneuverability:

Traditional forklifts require a lot of space to turn, but multi-directional forklifts can rotate on the spot thanks to their innovative wheel configurations. This exceptional maneuverability minimizes the need for broad turning areas, leading to more efficient use of warehouse space.

Increased Productivity:

The capability of moving loads in a lateral direction, such as sideways, is essential. The ability to move loads sideways and forward and backwards significantly reduces the time needed to position goods. Enhanced productivity translates into faster loading and unloading processes, improving overall warehouse throughput.

Safe Handling Of Long Loads:

Multi-directional forklifts are designed to handle long and heavy loads with ease. Their specialized attachments and lifting capabilities enable the safe and secure transportation of items like steel, pipes, and timber, reducing the risk of accidents and damages.

Versatility:

Combilift’s range of multi-directional forklifts can be adapted to suit various warehouse environments and load types. Whether indoor or outdoor operations, rough terrain, or smooth floors, these forklifts can handle diverse challenges, making them versatile assets for any warehouse.

Hence, approach HorvertInc, the best heavy-duty supplier of Combilift such as Combilift sideloader, straddle carriers, and various other material handling equipment for optimizing the warehouse and increasing efficiency.