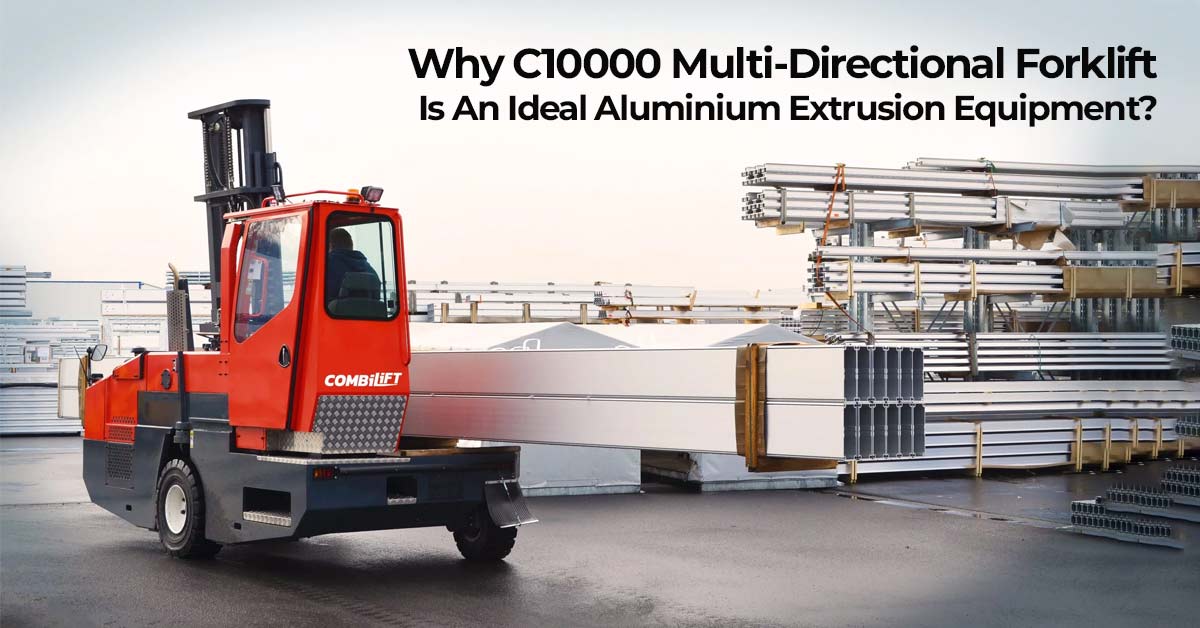

Multi-Directional Forklifts Enhance Extrusion Processes

In manufacturing, especially in industries dealing with heavy and long raw materials or billets for extrusion processes, the efficient handling of materials is crucial for seamless operations. Multi-directional forklifts play a pivotal role in this regard, contributing significantly to the smooth and streamlined movement of materials from the initial stages of production to the storage of final extrusion pieces in narrow aisle warehouses. In this blog post, we’ll explore how multi-directional forklifts contribute to the overall efficiency of these processes.

Versatility In Material Handling:

One of the critical advantages of multi-directional forklifts widely used at aluminium extrusion for their versatility in handling Long Extrusions and billets . These forklifts are designed to move forward, backwards, and sideways, allowing for precise maneuvering in tight spaces. Navigating through narrow aisles and tight corners is invaluable when dealing with heavy, long raw materials or billets destined for the extrusion process. Multi-directional forklifts excel in this aspect, ensuring that materials can be transported quickly and efficiently, minimizing the risk of damage or disruptions to the production flow.

Efficient Loading & Unloading For Extrusion:

Loading raw materials onto the die for extrusion is a critical step in the manufacturing process. Multi-directional forklifts enhance this process by providing operators with better visibility and control. The ability to move in multiple directions allows for precise positioning of the raw materials, ensuring accurate and efficient loading into the extrusion machine. It saves time and reduces the likelihood of errors, contributing to higher overall product quality.

Navigating Narrow Aisles In Warehouses:

Once the extrusion process is complete, the final shaped pieces must be stored in warehouses. Many manufacturing facilities need more space, requiring narrow aisles for storage. Multi-directional forklifts as aluminium extrusion equipment shines in this environment, as their unique design allows them to navigate tight spaces easily. This capability is especially advantageous when storing extruded pieces, as it maximizes warehouse space and facilitates organized and efficient storage practices.

Increased Productivity & Reduced Downtime:

Efficiency is a critical driver in the manufacturing industry, and multi-directional forklifts contribute significantly to increased productivity and reduced downtime. Their precise handling of materials and navigating constrained spaces streamline the production process. Operators can transport materials swiftly, load them onto the extrusion die, and move the finished products to storage without extensive maneuvering or adjustments. It saves time and minimizes the risk of accidents or damage during material handling.

Enhanced Safety Measures

Safety is paramount in any manufacturing setting, and multi-directional forklifts are designed with safety in mind. The improved visibility and control they offer contribute to a safer working environment. Operators can confidently navigate the production floor and warehouse, reducing the likelihood of collisions or accidents. It, in turn, enhances overall workplace safety and contributes to a more secure and efficient manufacturing process.

Using multi-directional forklifts as aluminium extrusion equipment in the extrusion industry significantly improves the handling of heavy, long raw materials Viz billets and the storage of F.G material Viz… extrusions in narrow aisle warehouses. Approach Horvert, one of the best heavy-duty suppliers, to become even more prominent in shaping the future of manufacturing.