The Anatomy Of A Forklift Truck

Horvet

It is no longer a secret that forklifts significantly improve an organization’s productivity and efficiency. Forklifts are one very important piece of equipment that can lift and transport loads across production or assembly lines and inside warehouses, as well as beneficial for outdoor applications If you are a startup and want to take your logistics business to the next step, investing in the Combilift side loader forklift multi-directional equipment and Combilift narrow aisle forklifts and stackers will greatly benefit you, as Combilift specialized in equipment that maneuverer within tight aisle width. Meaning space spacing. However, speaking of forklift trucks, let us know the primary and essential parts of the vehicle to use effectively. It is also true that knowing the in and out of the forklift will give you more insights into its safety which will help in the long run. Hence, in this post, let us know the forklift trucks’ basic systems, components, and necessary accessories.

Cabin:

The foremost part of the forklift trucks is the cabin, where the machine operator manages the entire operating system of the vehicle. All cabin is equipped with controls, steering wheel, brakes, accelerator paddles, life brakes, and the signal system, But the Combilift multi directional forklift is different, the cabin is located on one side of the equipment. this is so well placed, that the operator can see the load that is lifted without any mast blocking his vision, rest of the forklift has the cabinet behind the mast, so vision is partially hampered, but Combilift’s unique design of choosing and placing the cabin in one coroner offers a clear view to the operator not only in front but also on right-hand side and left hand side.

Similarly, the cabin of Combilift provides an enclosure model, so you need to choose the forklift by knowing the location, suppose it is situated in a terrain where you receive a lot of rainfall and the winters are extremely unbearable, most of the time, your forklifts will be inside, as you cannot operate outdoors due to weather condition and choosing Combilift which has steel forklift cabins, and has the option of the glass enclosure, wiper blades, heater and super clear windshield, Combilift multi-directional forklift for such application is a good investment.

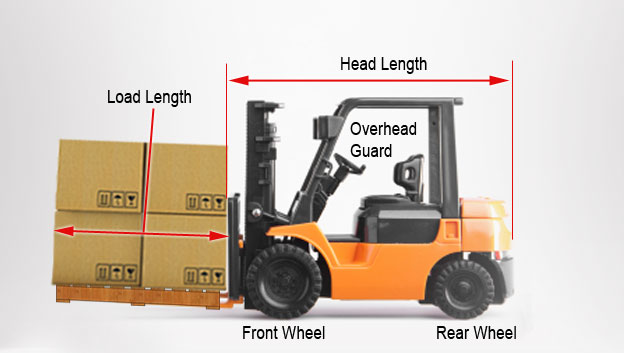

Overhead Guard:

It is simply a protective shield over the cabin protecting the operator from extreme weather conditions or the objects falling. Similarly, it is also essential to understand that the overhead guard is not created to balance the falling load’s entire weight, which can impact heavily. However, to overcome these defects, the forklifts are designed with the feature called “crush and deflect.” So, when a small or partial load falls on the overhead guard, the leg of the vehicle is designed in such a way that it can handle the load and reflect it back.

Forks And Counter Weight:

The forks are the essential components of the forklift truck which manages in lifting the cargos, pallets, and vice versa. A counterweight is nothing but a feature that balances the truck from tipping during the lifting of heavy loads.

But counterweight occupies a lot of volumes mostly at the rear in case of conventional forklift

Whereas Combilift Multi direction forklifts are just 55% in length of a regular normal forklift

The reason the counterweight is below the driver’s cabin. this keeps the forklift size small and compact to maneuver in tight aisle space.

Hence, these are major parts of the forklift truck that you should be aware of. Hence, approach Hovertinc, the best supplier of container lifting machine material handling equipment both for heavy materials and average loads, and we have solutions to meet all your requirements.

Related Articles

How To Achieve Maximum Space Utilization In Your Warehouse?

One of the critical factors in w

Read More

The Evolution Of Heavy-Duty Load Handling Forklifts

The industry of material handlin

Read More

A Comparison Between Multidirectional & Traditional Forklifts

Read More

How C10000 Forklift Is Ideal For Outdoor & Heavy Applications?

Read More

C5000 XL: The Heavy-Duty Material Handling Solution for Every Industry

Read More

Revolutionizing Material Handling: COMBI-SL4500 Multi Directional Forklift

COMBI-SL4500 Read More

A Guide On Maximizing Warehouse Efficiency with the COMBI-CB Forklift

Efficiency is paramount in moder

Read More

How C-Series Multidirectional Forklift Helps Food Manufacturers?

Read More

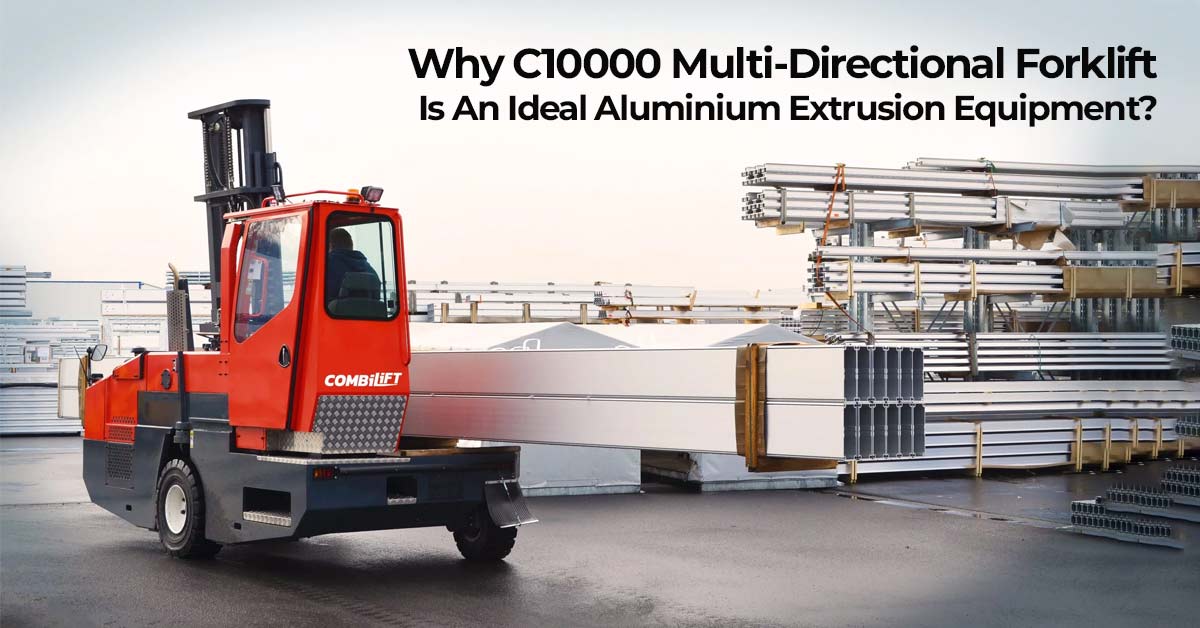

Why Combilift Model -C4500 E Multi-Directional Forklift Is An Ideal Aluminium Extrusion Equipment?

Read More

Things You Need To Know About COMBI-4WSL Forklifts

Read More

How Heavy Duty Cantilever Racks Are Best For Industrial Storage?

Read More

How is COMBI-CBE Multi Directional Forklift Used In the Timber Industry?

Read More

Know Why Choosing COMBI-FWSL is Ideal For the Steel Industry

Read More

Know About The Special Features Of COMBI-MR Multi Directional Forklift

Read More

COMBI-WR4 The Best Pipe Handling Equipment – Why?

Read More

Multi-Directional Forklifts Enhance Extrusion Processes

Read More

How To Create Safer & Efficient Storage Facilities?

Read More

How Does Your Truck Selection Impacts On Forklift Safety?

Read More

How Does Combilift Series Help You In Optimizing Your Outdoor Space?

Read More

Why COMBI-MR4 Is A Must In Logistics?

Read More

How Forklifts Help In Overcoming The Warehouse Challenges?

Warehouses play a crucial role in logistics, retailers, and many

Read More

Things To Consider In Calculating Forklift Aisle Width

The forklift is one such equipment that makes your warehouse or

Read More

How To Prepare For A Material Handling While Using A Forklift?

We all know that forklifts significantly enhance the warehouse's

Read More

Guidelines To Consider While Using Forklifts In Outdoors

Forklifts are one such heavy-duty equipment , its contribution �

Read More

Things You Need To Know About Lockout/Tagout Procedure

We all know that a forklift is o

Read More

Tips To Find The Right Forklift Model For Your Job

If you are into logistics or warehouse activities, then you migh

Read More

How Often Should You Service The Forklift?

The warehouses and industries have tons of goods to deliver and

Read MoreBenefits Of Forklift Tracking And Monitoring System

Forklifts have become one of the essential equipment in the logi

Read More

Which Lift Truck Is Best For Warehouse Facilities?

The warehouse is one of the most happening places where manufact

Read More

Tips On Preventing Forklift Damage

The workplaces like distribution centres, warehouses, logistics,

Read More Previous

Previous

Next

Next

No. 218, 4th Cross, Second Floor, Bhuvaneshwary Nagar Velachery, Chennai – 600042, Tamil Nadu, India

Get A Quote

Designed by Corporality Global