The Hidden Costs Of Inefficient Material Handling—And How Combilift Solves Them

The world of logistics and warehousing needs efficient material handling to meet the evolving needs of the industry which has become necessity over luxury. So, many businesses continue to overlook or underestimate the true costs of the inefficiencies in this area. Hence, as a result businesses face operational delays, damaged goods, workplace injuries, space underutilization, and many which quickly adds up leading to the hidden expenses. Fortunately, with the innovative solutions from Combilift’s multidirectional forklifts you can streamline the complete warehouse operation, reduce the losses, and boost productivity significantly.

The Real Cost of Inefficiency

As per the reports from the Occupational Safety and Health Administration (OSHA), many businesses which often overlooked or underestimated the efficiency of the material handling tend to lose around $62 billion annually. This often included workplace injuries, not utilizing the space efficiently and more. Hence, as a result these inefficiencies harm the workers and result in downtime, compensation claims, and reduced workforce.

Space Utilization:

The costs go beyond safety and one of them is space utilization. It is because the traditional forklifts require wider aisles which typically tend to range around 12 to 14 feet leading to the underused warehouse space. Also, the studies show that efficient warehouse layout and narrows aisle solutions can increase the storage capacity by 50%

Damage To Goods And Equipment:

Also, inefficient material handling and narrow spaces can often result in the damaged inventory and equipment. As per the reports from Logistics Management survey around 18% of the warehouse’s losses were due to the material mishandling.

Time Wasted:

Moreover, the pathways that are unoptimized and inadequate equipment can often lead to longer travel times and delays during the loading and unloading. The report from the Materials Handling Institute states that improving the handling efficiency of companies can save up to 20%-30% annually in time and labor costs.

How Combilift Turns The Tables?

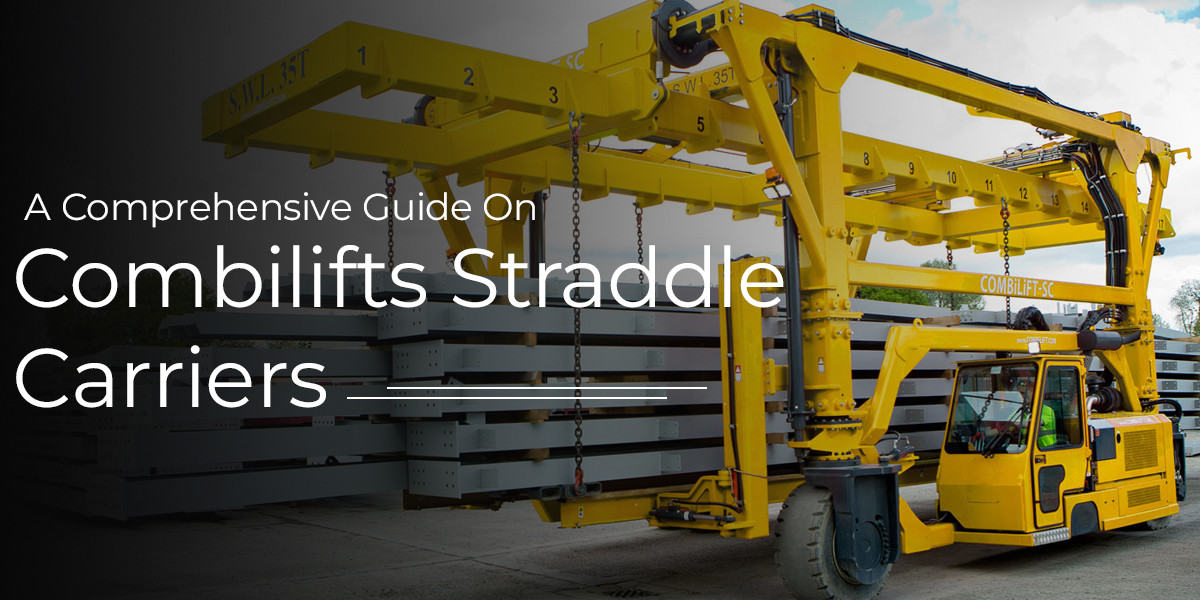

The introduction of the Combilift, the global leader in multi-directional forklift and customized handling solution helps your business to manage your operations, overcome the challenges, enhanced safety, and exceptional operational efficiency.

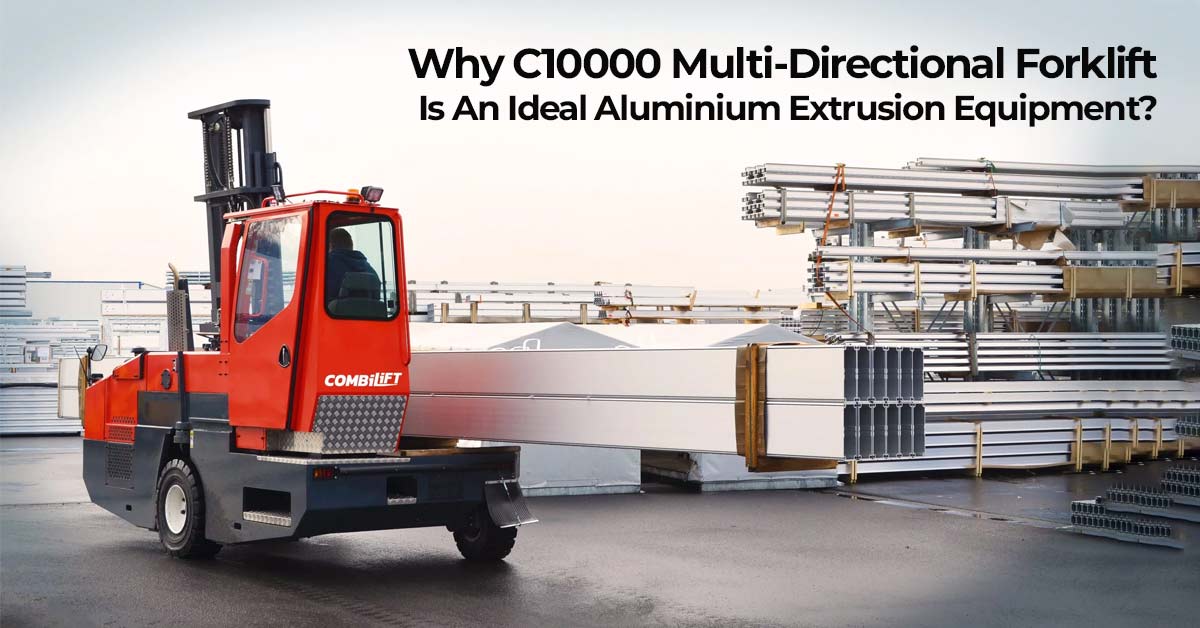

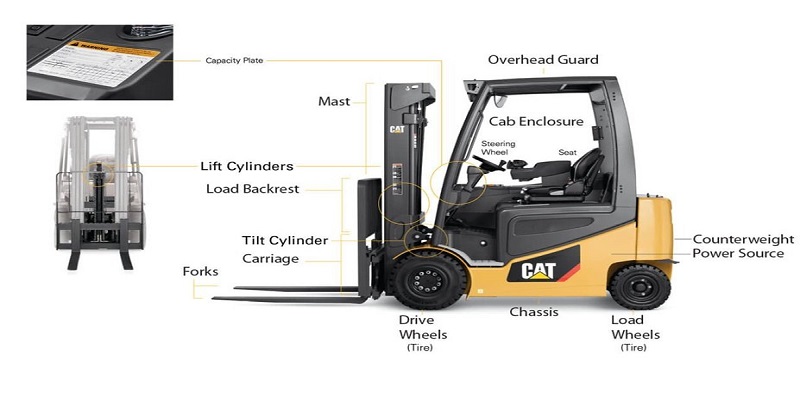

Multidirectional Movement

The traditional forklifts can only move either forward or backward with limited maneuverability within the confined area. With Combilift’s multidirectional technology businesses can effectively make their operations seamlessly with the help of equipment which easily moves forwardly, backwardly, and sideways. This facility makes them ideal for handling long and bulky loads in the narrow aisles. Also, with these you can reduce the aisle width up to 50% improving warehouse capacity.

Space Optimization

The Combilift equipment allows the businesses to optimize the entire racking systems which helps in using the vertical and horizontal space. A recent survey states that an European Timber Company has reported that with the help of Combilift equipment there was around 30% increase in the storage capacity.

Safety First

Also, Combilift Forklifts has excellent features like 360-degree visibility, integrated camera systems, and low center of gravity enhancing the operators safety. Moreover, the company also integrates with the auto-reverse features and collision sensors which reduces the workplace accidents which was the key factor of hidden costs in traditional warehouses.

Custom Engineering

It is indeed a fact that no two warehouses are the same. Hence, with this focus the Combilift is designed which is customized for handling solutions tailored as per the specific industry needs. Despite the steel, timber, manufacturing, and retail industry, the Combilift equipment offers excellents solution ensuring optimal performance and reducing the need for multiple types of equipment.

Reduced Operational Costs

It is indeed a fact that a logistics firm in the UK reported a 20% reduction in handling time and around 15% in the operational costs after incorporating Combilift solutions. Hence, the ability to handle all the materials with fewer machines allows the businesses to reduce the labor, energy consumption, and maintenance costs.

As global supply chains become more complex and warehouse space more expensive, the importance of efficient material handling will only grow. Investing in advanced solutions like those from Combilift is not just about modernizing—it’s about surviving and thriving in a competitive market.

Whether you’re managing long metal pipes, awkward pallet sizes, or simply want to make the most of your storage, Combilift’s versatile range of forklifts ensures that your material handling is efficient, safe, and cost-effective.

Inefficient material handling is a silent profit killer. The statistics paint a clear picture of how it can drain resources, increase risk, and limit growth. With Combilift’s innovative solutions, companies can transform these hidden costs into tangible gains—turning efficiency into their strongest asset.